Induction Pipe Bends

Induction pipe bends, also known as weld less pipe spools, are pipes bent at desired angles and are manufactured through high frequency induction bending. Induction bending uses induction coils to generate extreme heat in the area of pipe which needs to be bent. The heated section is then moulded by a fixed arm and bent to get the desired angle. We manufacture seamless, LSAW induction pipe bends in the material grades of carbon steel, alloy steel, austenitic steel, stainless steel, super duplex stainless steel and incoloy materials. We specialise in alloy steel grade P91 and P92 air-quench induction bends and stainless-steel induction bending. Induction pipe bends are used in various industries like power (thermal and nuclear), oil and gas, petrochemical refineries, process industries, desalination plants and cement industries.

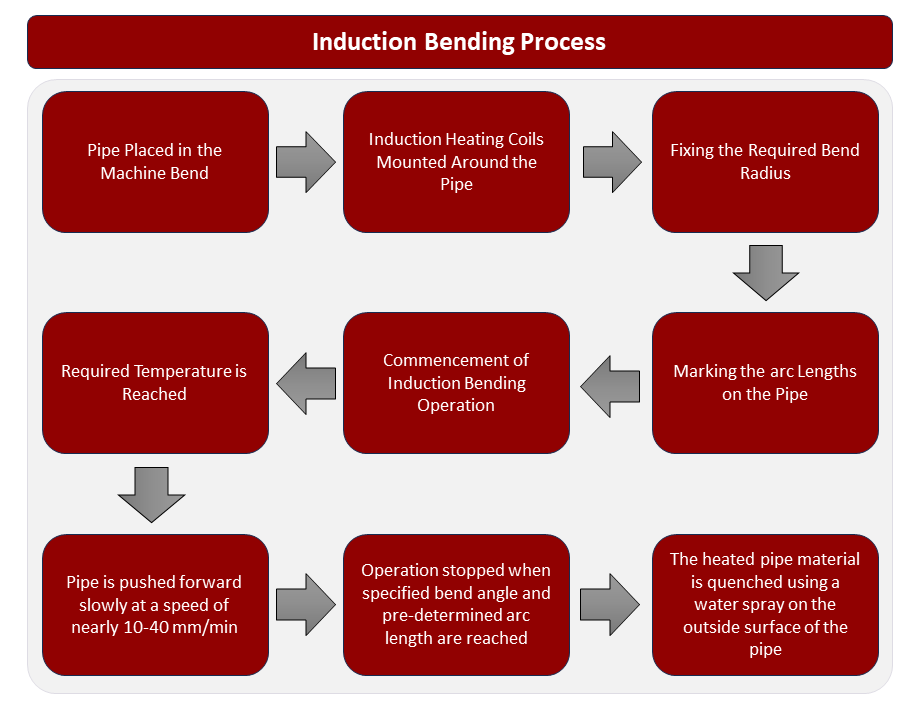

Induction Bending Process