We provide comprehensive specialized process piping solutions including engineering services such as pre bid engineering, basic engineering, detailed engineering and support engineering which includes engineering of process/ power piping systems for projects, and pre-fabrication services such as cutting and bevelling on conventional and CNC machines, welding services on semi-automatic and fully automatic robotic welding machines, conventional and digital radiography, post weld heat treatment using CNG fired fully calibrated furnaces and induction heating process, hydro testing, pickling and passivation, grit blasting (manual and semiautomatic) and painting (manual and semiautomatic).

We also specialize in handling complex metals such as varying grades of carbon steel, stainless steel, super duplex stainless steel, alloy steel and other materials including Inconel and Hastelloy in our manufacturing processes.

Have A Project!Services For Multiple Industries And Technologies!

Shop Fabricated Piping

We provide comprehensive specialized process piping solutions including engineering services such as pre bid engineering, basic engineering, detailed engineering and support engineering which includes engineering...

More

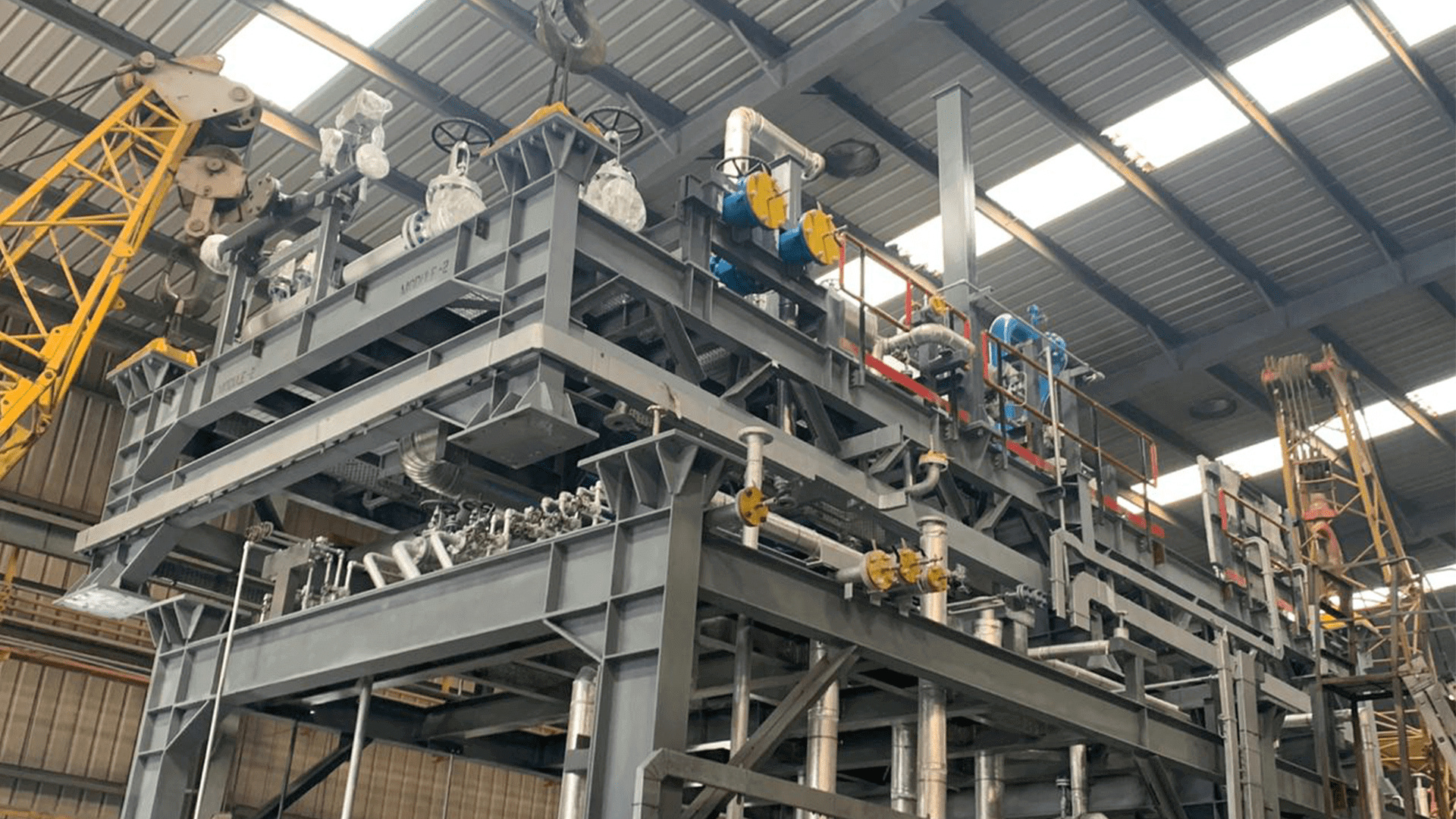

Skid & Modular Piping

We offer advanced specialized process piping solutions to our customers for pipe rack and processing structures by way of modular skids. These modular skids have a wide range of applications in the petrochemicals and natural...

More

High-Frequency Induction Bending

Induction pipe bends, also known as weld less pipe spools, are pipes bent at desired angles and are manufactured through high frequency induction bending. Induction bending uses induction coils to generate extreme heat in the area...

MoreRegulatory Compliance

Regulatory compliance across every country of operation and partnership is our mainstay

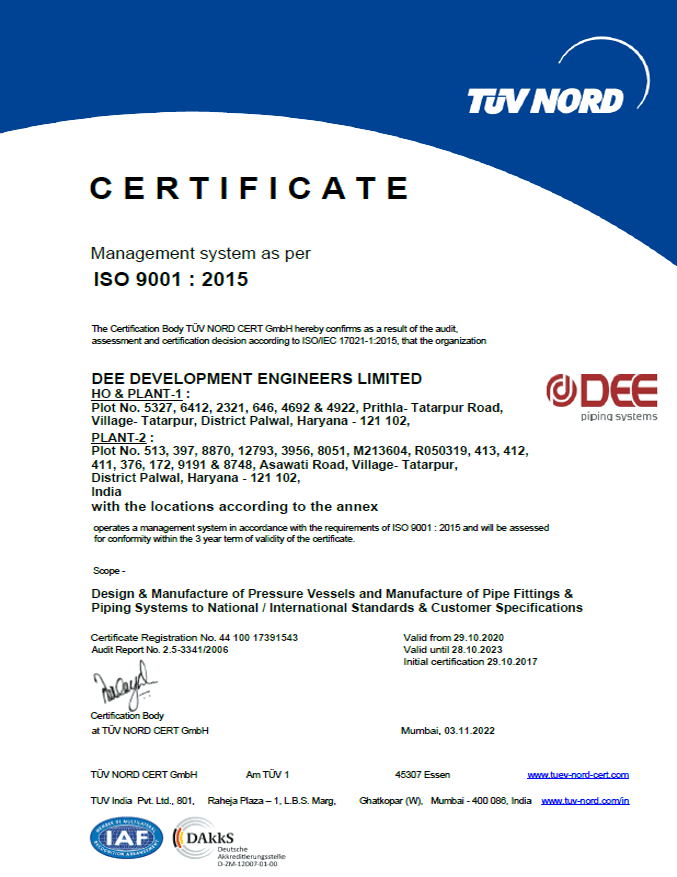

ISO 9001 : 2015

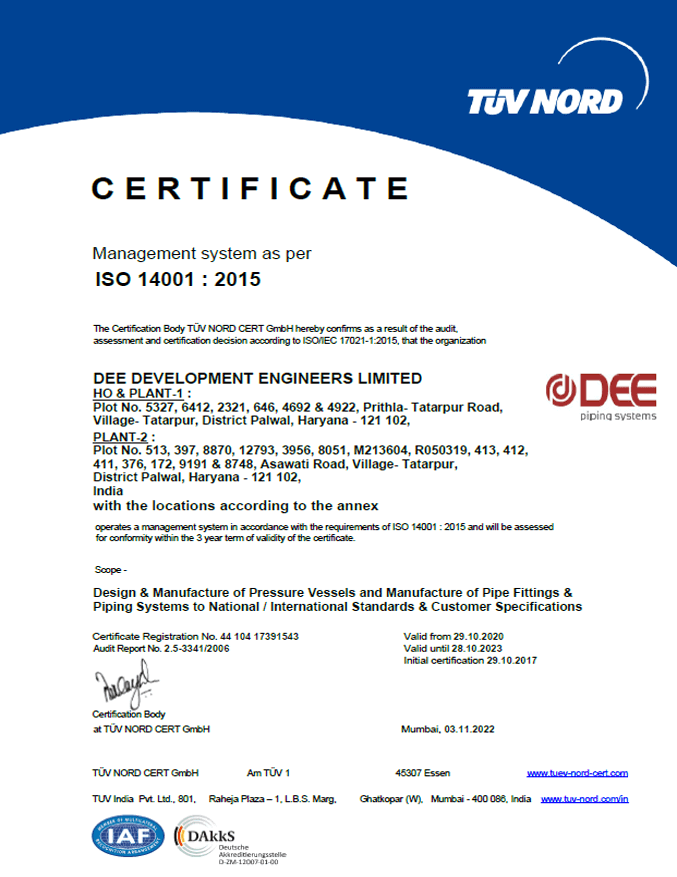

ISO 14001 : 2015

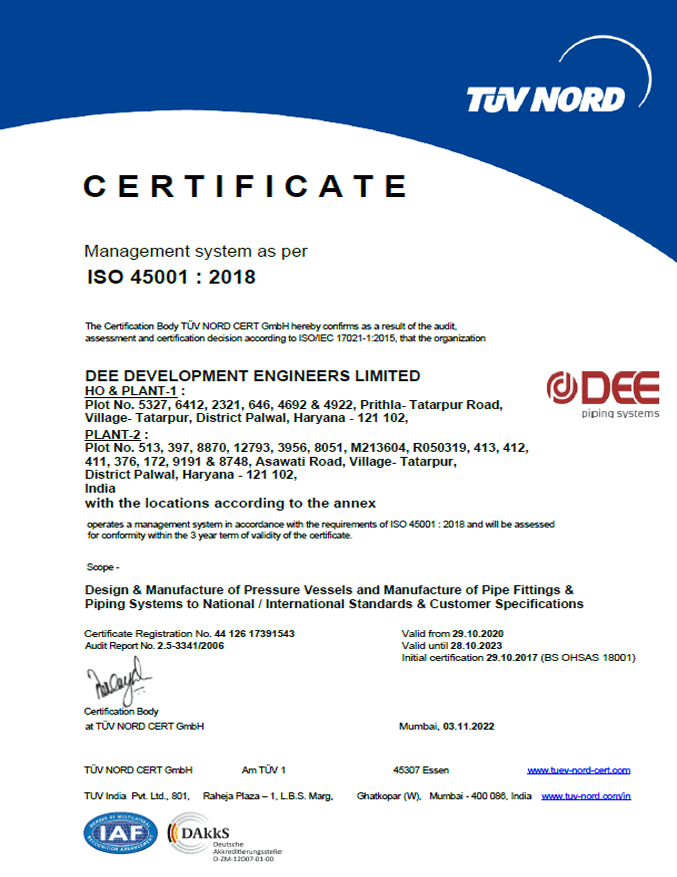

ISO 45001 : 2018

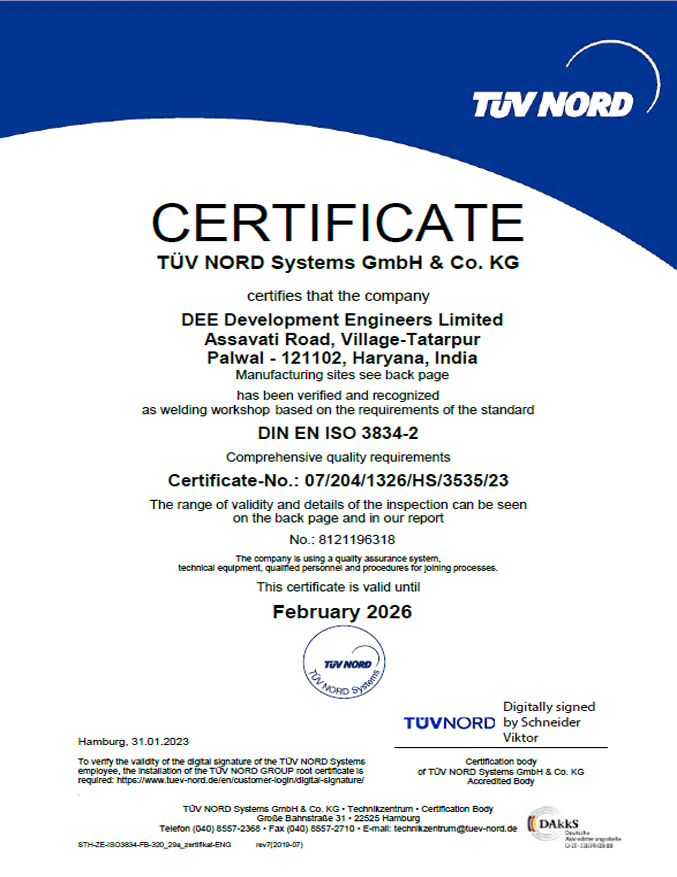

ISO 3834-2:2007

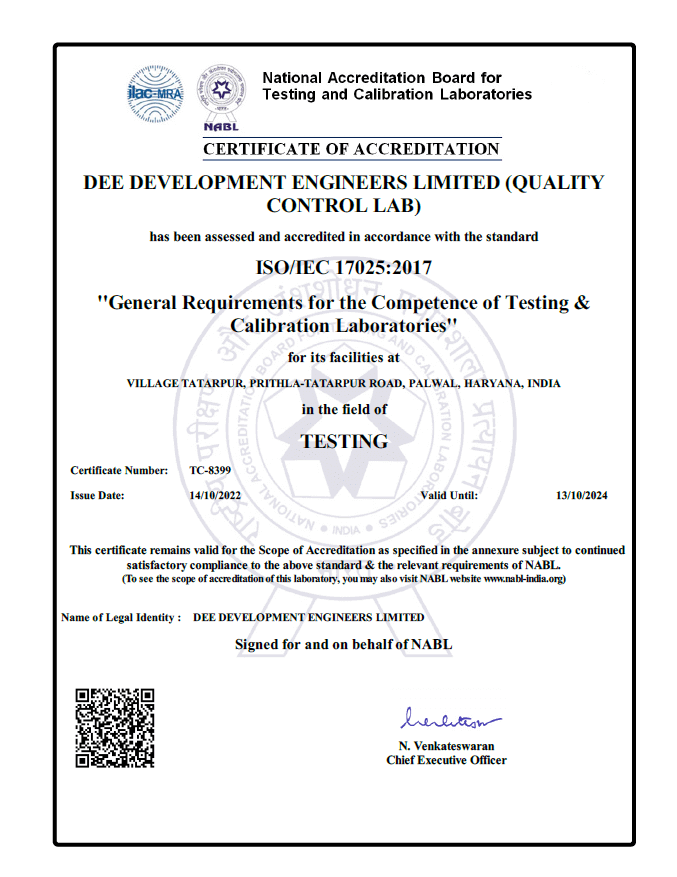

ISO 17025-2017 NABL Certification

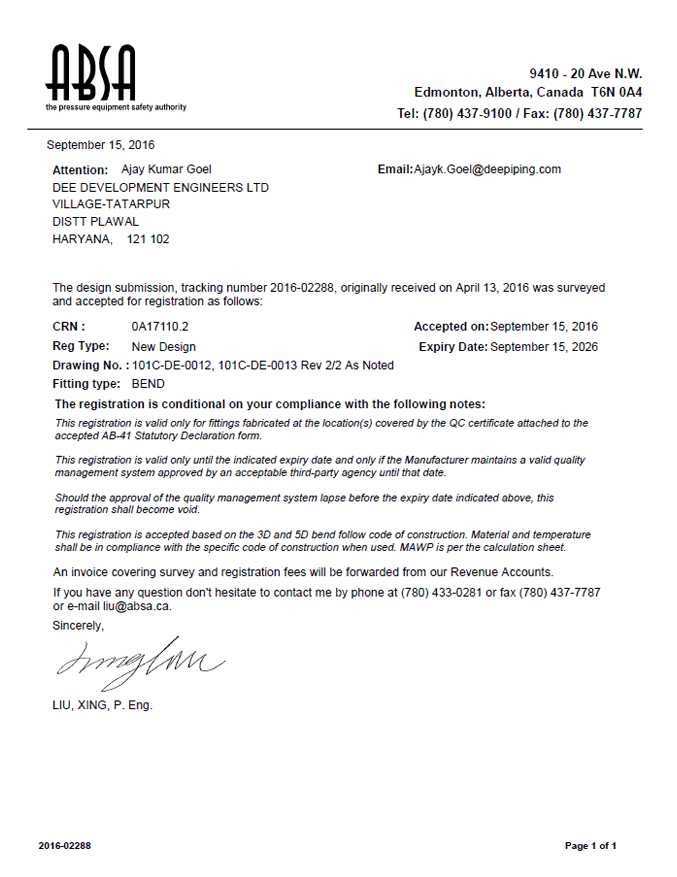

CRN Certification

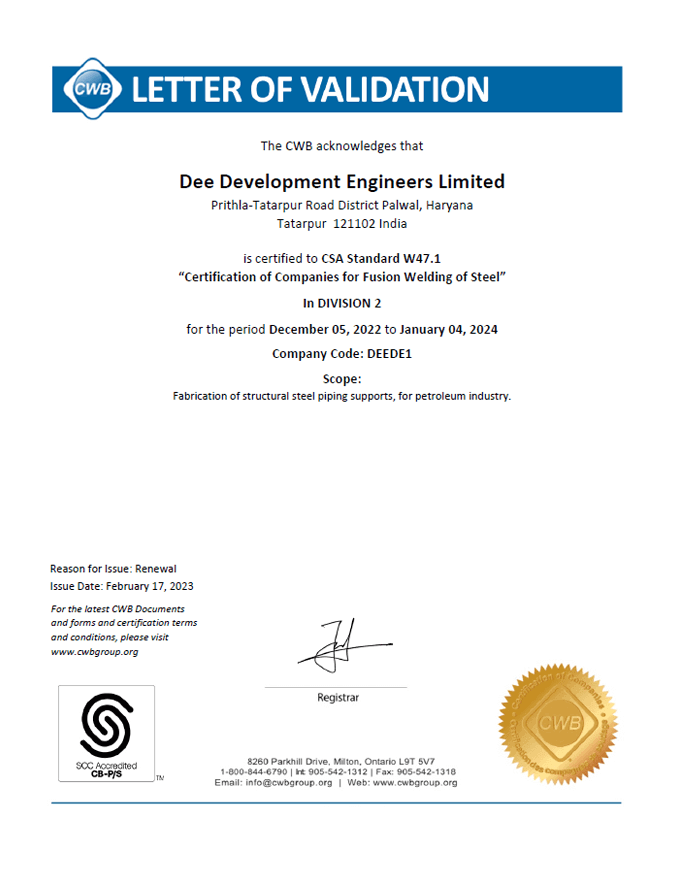

CWB Certification

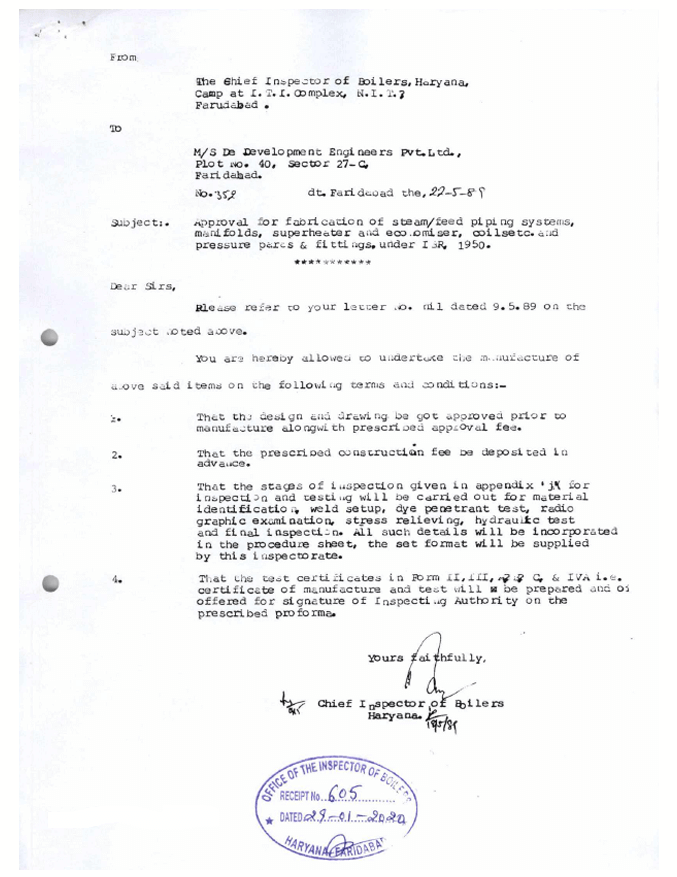

IBR Certification

.png)

ASME PP

.png)

ASME PP

.png)

ASME S

.png)

ASME S

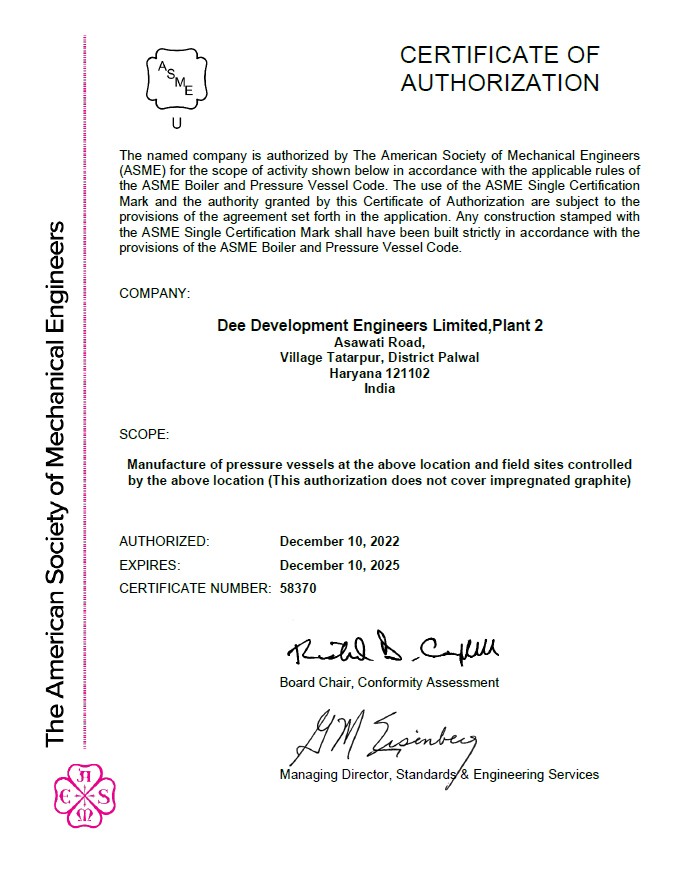

ASME U

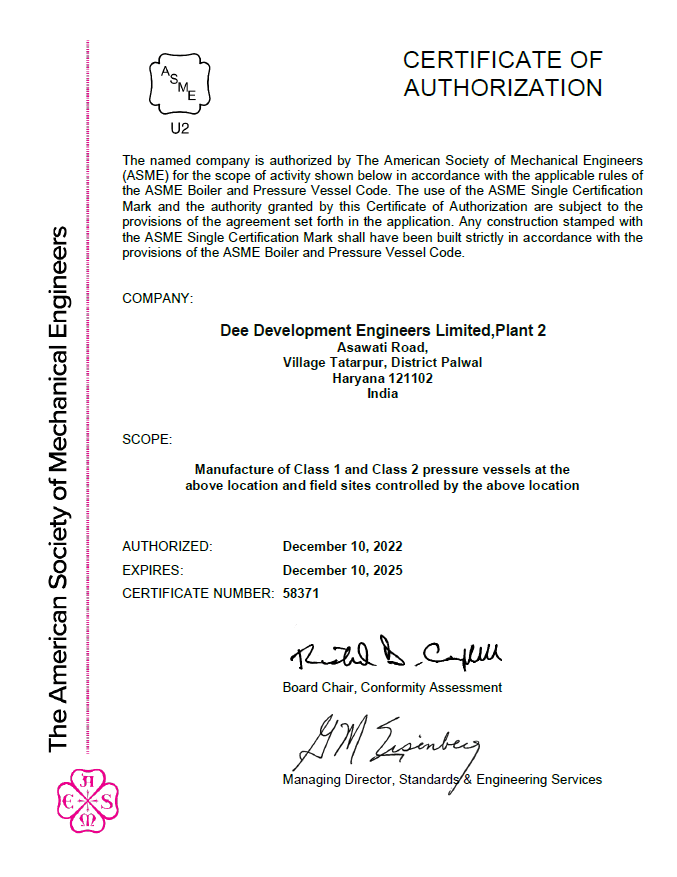

ASME U2

PED Fitting Certificate

.png)

National Board Certification (Plant-II)

What Our Clients Say!

DEE Team approach was extremely positive and proactively supported to resolve the issues. The quality and attention to detail, and commitment to meeting our needs have been truly outstanding. Ability to provide timely updates and clear communication throughout the process helped us to alleviate any concerns and ensure successful delivery.

It was a pleasure working with you and your team. We value your partnership & we look forward to continuing to work with M/s DDEL in the future.

Thank you again for the outstanding work, and please pass on our appreciation to your entire team.