Overview

Our quality policy is focused on fulfilling customer requirements through reliable products and services aimed at meeting all regulatory requirements and through continuous improvement of our quality management systems. Our products undergo a qualification process throughout the entire value chain to ensure that quality products are being provided to our customers.

Our customers demand the highest quality from us and to meet their expectations, we have developed in-house multilevel quality control processes. These quality control measures range from the initial inspection of raw materials and other parts and components to the continuous improvement of our business processes at each step in the production of our products, including periodic reviews of our quality management systems. Our manufacturing infrastructure is complemented by our stringent quality and safety standards and processes. Through our regular internal audits, we ensure that our manufacturing facilities are in compliance with local regulatory requirements as well as the requirements stipulated by our customers. We utilize an ERP system to trace each material and processes which helps us identify the root cause of a problem if it occurs and to take measures against the problems identified.

Given the nature of application of our products and engineering processes to critical industries such as oil and gas and power (including nuclear), our products and engineering processes are measured against, high quality standards and stringent specifications of our customers. These specifications are provided by our customers through technical specifications and quality standards forming part of the contracts which we enter into with our customers.

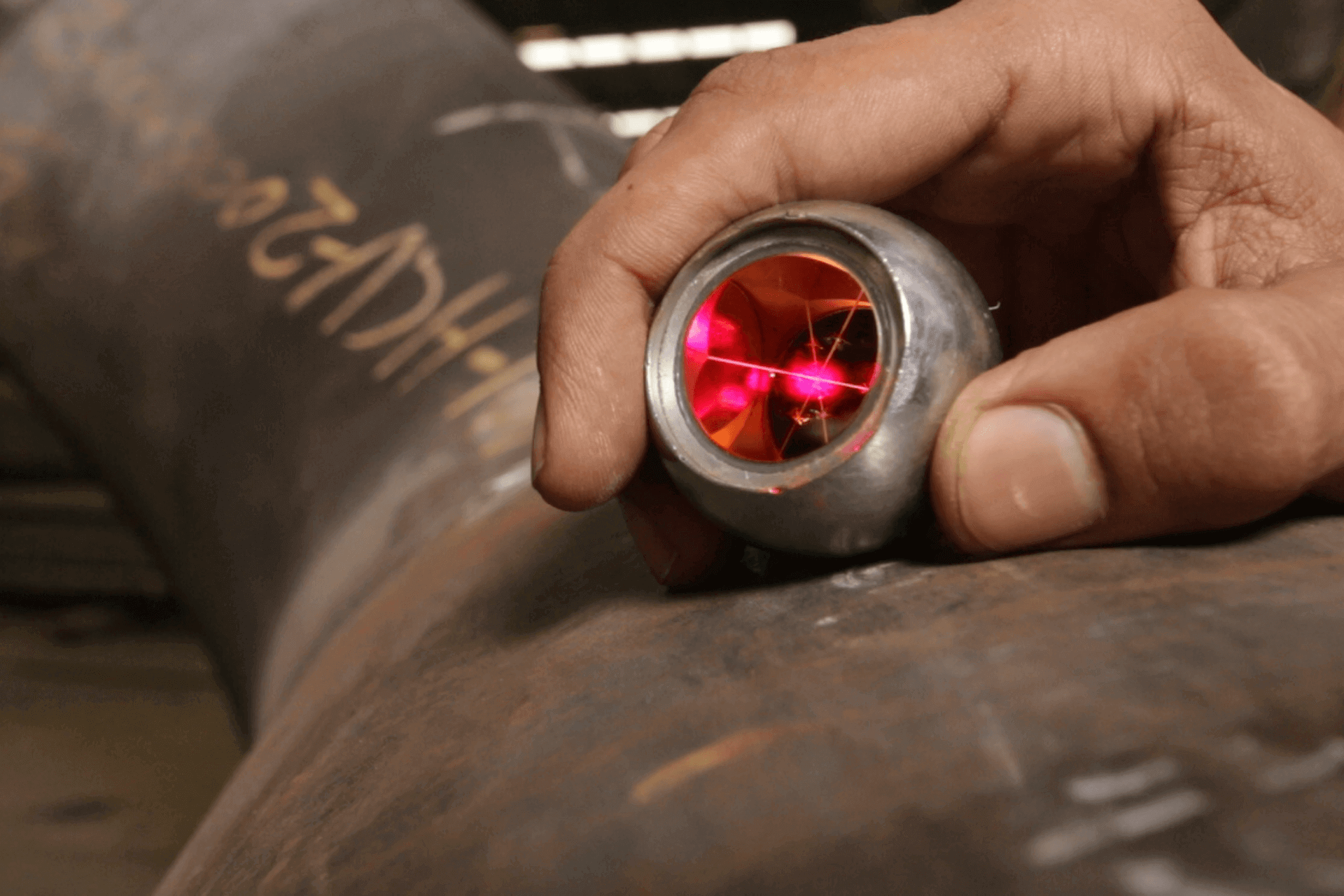

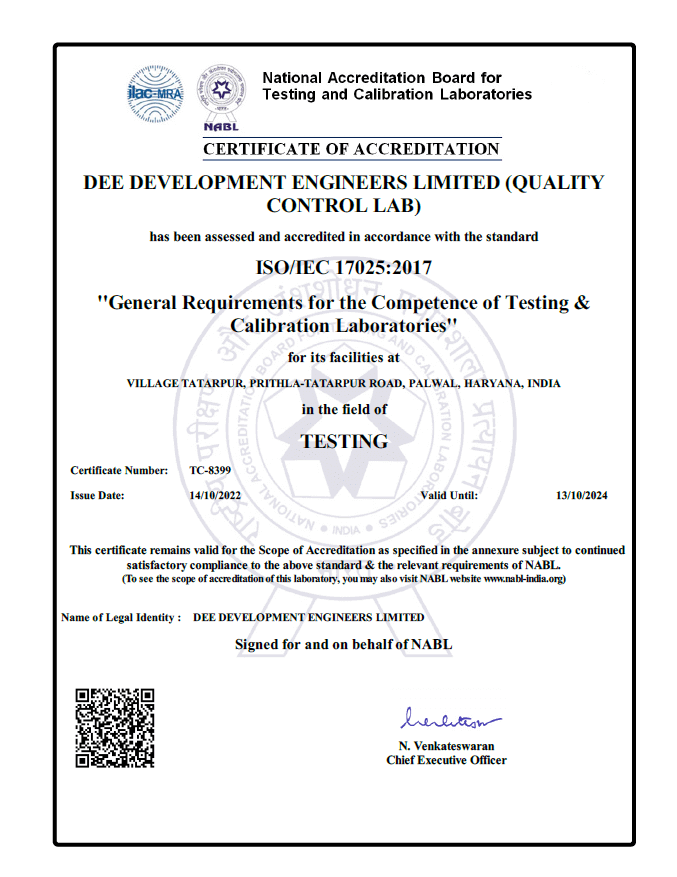

We also have a National Accreditation Board for Testing and Calibration Laboratories accredited testing laboratory where we undertake mechanical, metallurgical, chemical and analytical test such as tensile test, charpy test, hardness test, tests for micro and macro structure, spectrometric analysis, corrosion test, ferrite test, IGC test, bend test and flattening test amongst others. Our centralised non-destructive testing facilities are equipped with phased array ultrasonic testing, magnetic particle testing, visual inspection, radiography including computerised any digital radiography and dye penetrant examination.

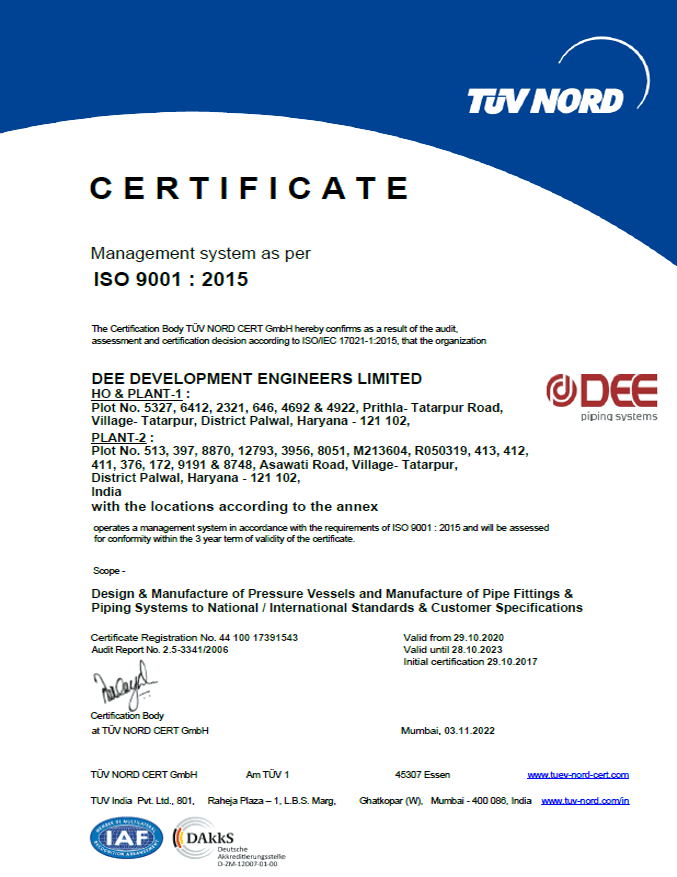

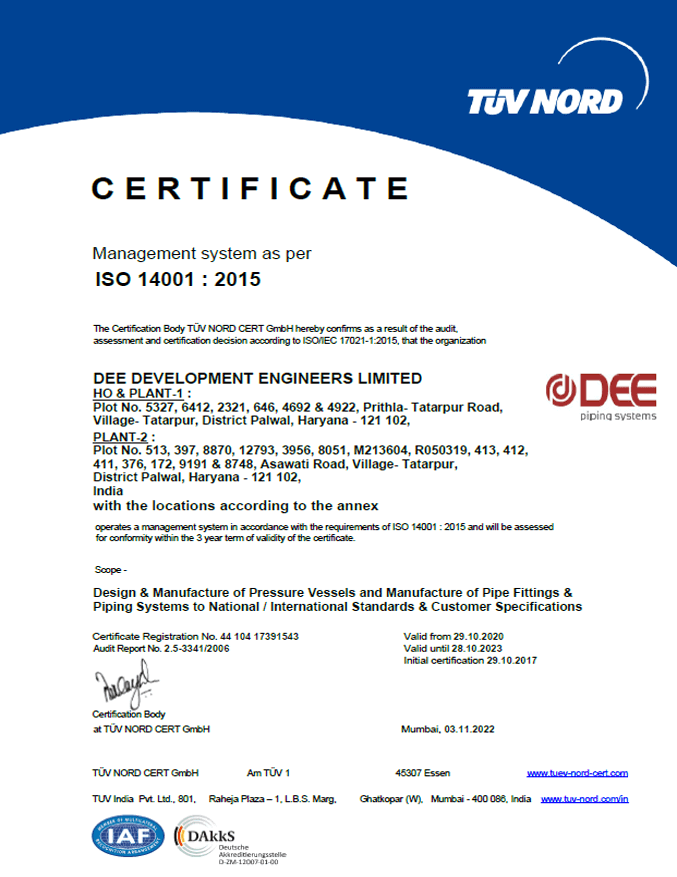

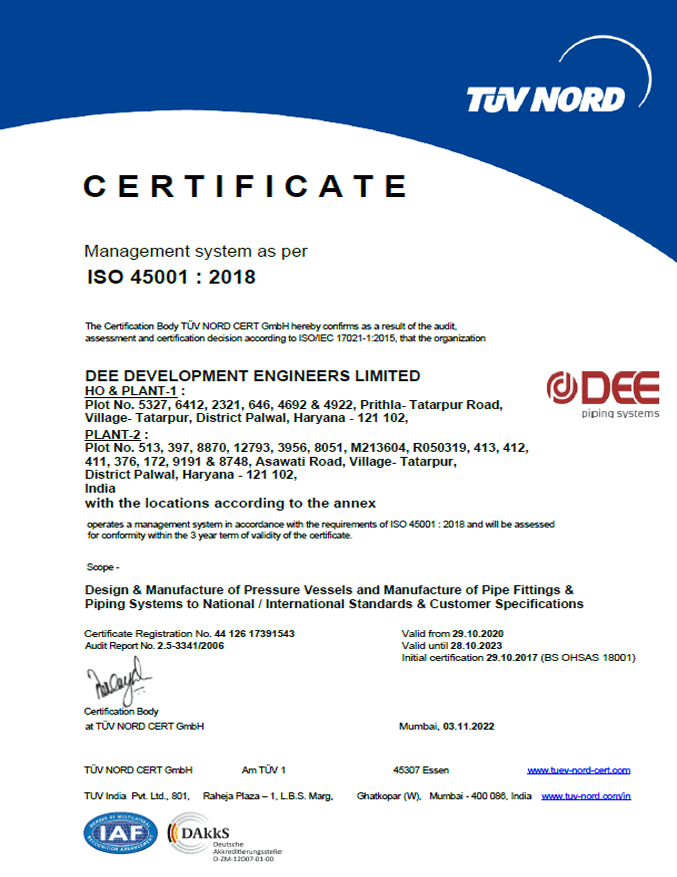

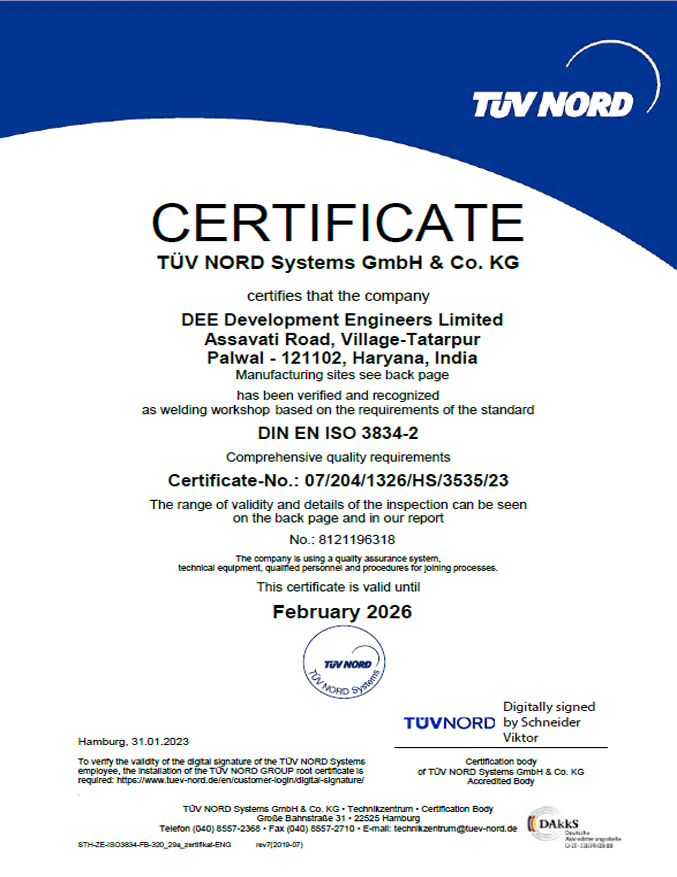

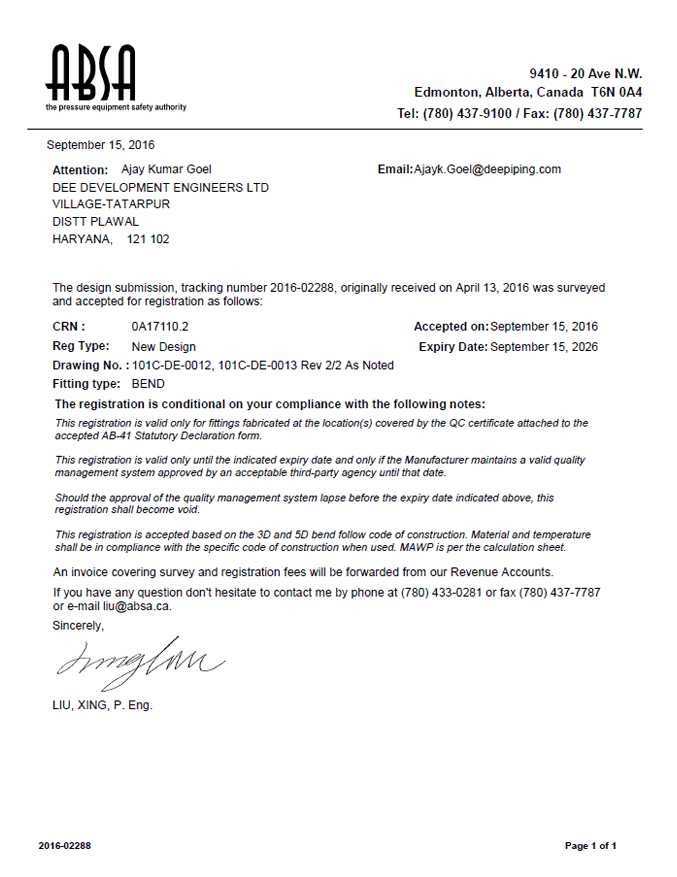

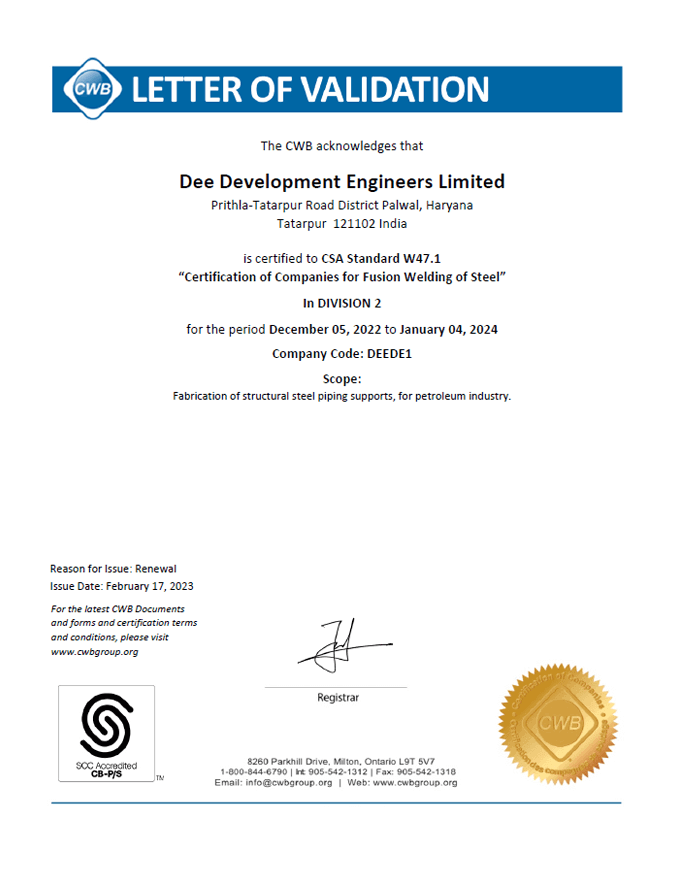

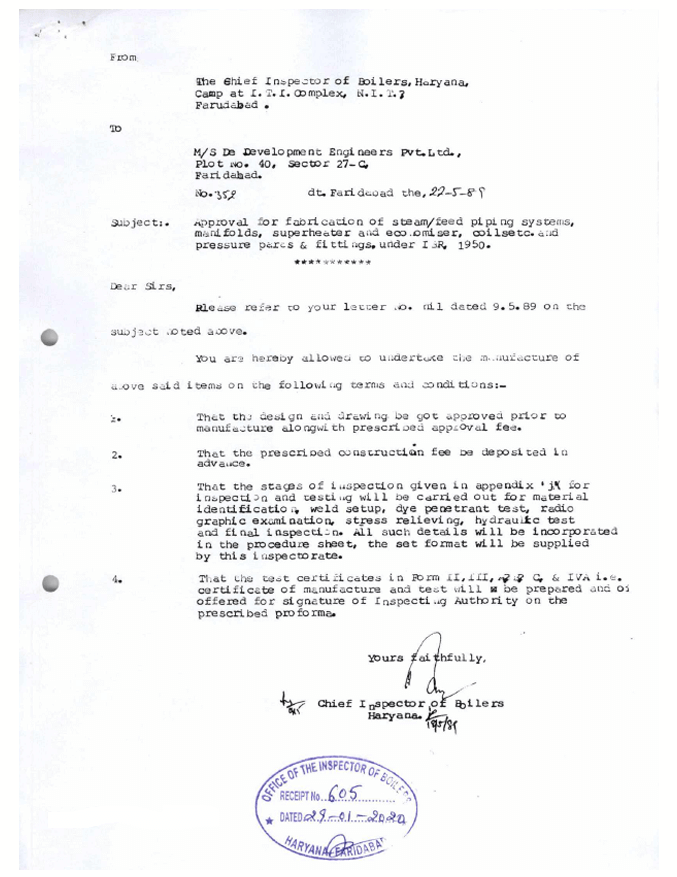

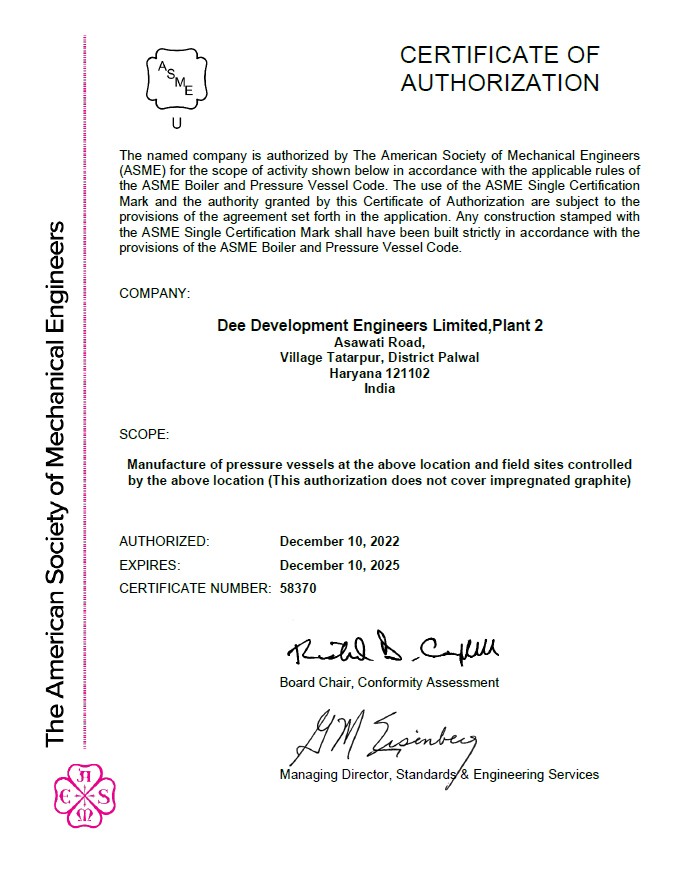

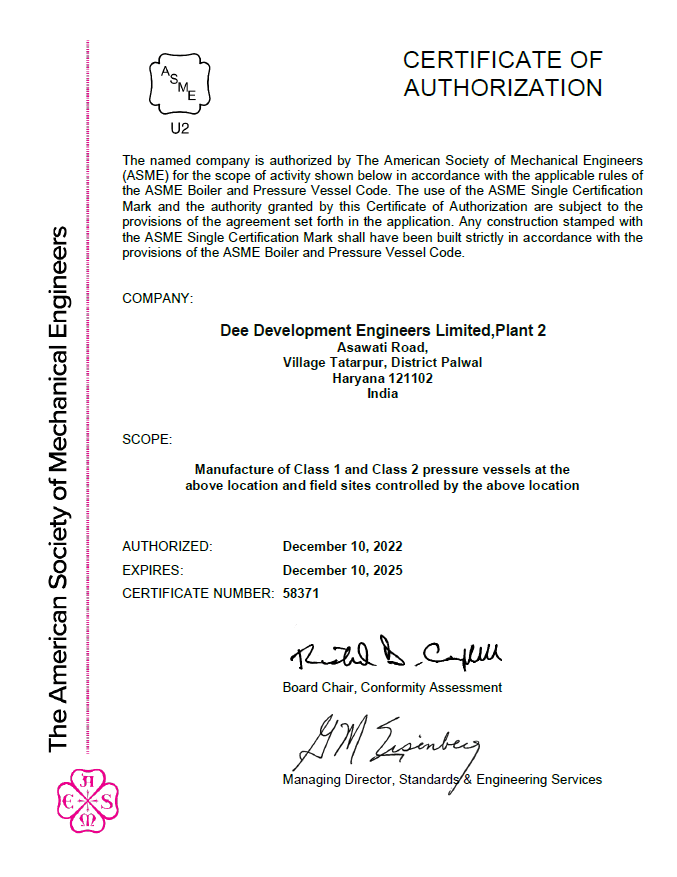

Our Company has acquired the following certifications and accreditations for our facilities:

We intend to continue focusing on automation and process excellence to increase operational efficiency. We have a team of 148 quality assurance and quality control engineers and more than 58 employees who are qualified as level II and III NDE personnel from accredited agencies responsible for ensuring quality standards. In executing the projects, we monitor and test all materials for conformity, track non-conformities and make rectifications to ensure customers’ satisfaction. Our quality assurance and quality control team ensure compliance with our quality management systems and statutory and regulatory compliances. This team conducts pre-dispatch inspection of our products.

In addition, our manufacturing facilities are subject to compliance audits in relation to quality management by third party agencies. Our customers expect us to undertake extensive product approvals and/or certification process and some of our customers also perform their own quality checks to ensure that our products meet their demands and comply with the requirements.

.png)

.png)

.png)

.png)

.png)